PRODUCT

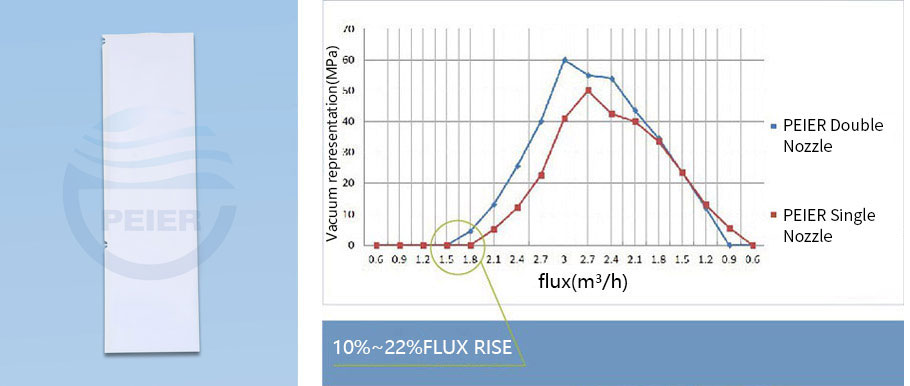

According to the comparative experimental study of critical flux test, the flux of double outlet membrane element can be increased by 18% ~ 22% compared with the traditional flat membrane element, so as to reduce the capital construction cost of the project; The chemical cleaning effect improves the phenomenon of pollution dead corner of single channel flat membrane element, improves the unit effective utilization rate and prolongs the service life of membrane element; Low transmembrane pressure difference can save operation cost and greatly enhance the market competitiveness of MBR.

Specification of Flat Sheet Membrane Element- Double Nozzle

| Flat Sheet Membrane Element - Double Nozzle | ||||

| Model | MF-F-1.5II-PVDF(PE150II) | |||

| Effective Membrane Area m²(ft²) | 1.5(16.1) | |||

| Dimensions (L×W×T) mm (in.) | 1780×510×7.5 (70.1×20.1×0.3) | |||

| Materials | Membrane | PVDF+PET (non-woven fiber) | ||

| Nominal Pore Size (μm) | 0.1 | |||

| Support Plate | ABS | |||

| Aeration rate (L/min.pcs) | 12 | |||

| Weight: dry/wet kg (lbs.) | 5.8/11 (12.8/ 24.2) | |||

| Effluent suspended solids (Mg/L) | ≤5 | |||

| Effluent turbidity (NTU) | ≤1 | |||

| MBR Operating parameters of flat membrane | ||||

| Temperature | 5-45℃(41-113°F) | |||

| pH of Liquid | 5-10 | |||

| Inlet Requirements | Fine Screen ≤ 3mm | |||

| Mixed Liquor Suspended Solids MLSS (mg/L) | 6000-12000 | |||

| Transmembrane Pressure(kPa) | ≤35 kPa (5.1 psi) | |||

| Operation mode of self-priming pump | Operation 8mins,stop 2mins | |||

| Aeration | Continuous Aeration | |||

| Operating water level Submerged Module mm(in.) | ≥300 (11.8 in.) | |||

| Chemical Cleaning in Place (CIP) | ||||

| Chemical Cleaning in Place (CIP) | Organic pollution | Sodium hypochlorite + sodium hydroxide | ||

| inorganic pollution | Oxalic acid or citric acid or hydrochloric acid | |||

| Cleaning Chemicals and Concentrations (mg/L) | 3000-5000 | |||

| Chemical Required (L/pcs) | 5 | |||

| Dosing method | Gravity dosing ≤10kPa(1.45 psi) | |||